Latest News

A mother bear and her cubs move through a backyard in northwest Connecticut, where residents told DEEP that bear litters are now appearing more frequently.

By James Clark

SHARON — About 40 people filled the Sharon Audubon Center on Wednesday, Dec. 3, to discuss black bears — and most attendees made clear that they welcome the animals’ presence. Even as they traded practical advice on how to keep bears out of garages, porches and trash cans, residents repeatedly emphasized that they want the bears to stay and that the real problem lies with people, not wildlife.

The Connecticut Department of Energy and Environmental Protection (DEEP) convened the meeting as the first in a series of regional Bear Management Listening Sessions, held at a time when Connecticut is increasingly divided over whether the state should authorize a limited bear hunt. Anticipating the potential for heated exchanges, DEEP opened the evening with strict ground rules designed to prevent confrontations: speakers were limited to three minutes, directed to address only the panel of DEEP officials, and warned that interruptions or personal attacks would not be tolerated.

“We really want to hear from you,” said Justin Davis, DEEP’s bureau chief for natural resources, at the meeting. He said that DEEP is preparing a bear management report in early 2026 that evaluates the challenges the state is facing and the strategies going forward dealing with them. He said the report will include feedback from the public generated at the listening sessions. He urged attendees, however, not to turn the meeting into a discussion about whether there should be a hunt or not.

Davis called the return of black bears to Connecticut a “conservation success story,” but one that now comes with challenges. "They're large animals, they're powerful and they can become comfortable being around people--and they're opportunistic, and they love to eat."

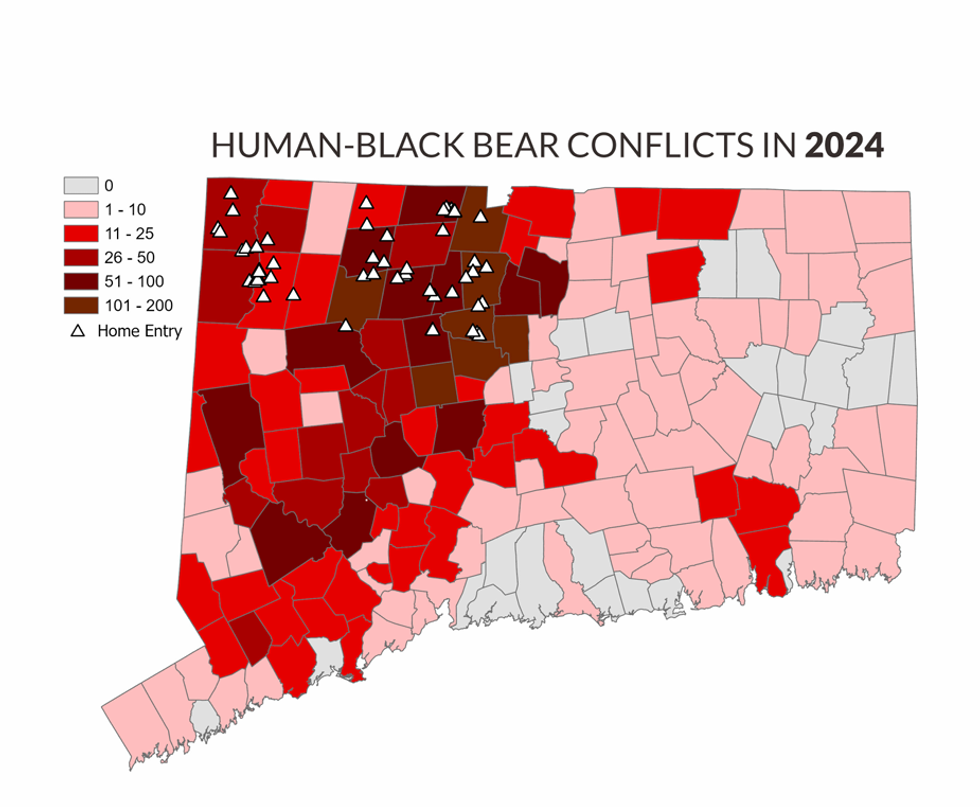

DEEP shared data showing that black bears have been reported in nearly every Connecticut town and that conflicts involving trash, bird feeders, livestock and home entries have increased sharply in recent years. The state’s bear population was last estimated at roughly 1,100 to 1,200 animals, a number that DEEP recognizes has grown since the study was conducted in 2012.

Eric Hammering, the office director of Environmental Review & Strategic Initiatives at DEEP, told the attendees that since 2020 there have been 264 reported home entries in 38 municipalities in northwest Connecticut, citing data from the state's State of the Bears report released in March.

A home entry, he said, is defined as an event when a bear actually goes inside a resident's living space.

DEEP officials stressed that bird feeders and unsecured household trash are the two biggest drivers of bear conflicts. They advise residents to remove feeders entirely and keep their garbage inside or in bear-resistant containers. DEEP representatives noted that once a bear discovers food, it is likely to develop habits and return.

Many attendees said they see widespread noncompliance in their neighborhoods — particularly among part-time residents and short-term rental guests who leave trash out for days. Several said they were frustrated that the people causing the problem are often not the ones who attend sessions like this.

As a result, a number of residents called for stronger statewide enforcement, including fines for leaving trash unsecured and penalties for repeated violations. Without consequences, they said, the same households will continue to attract bears and put neighbors at risk. Others described practical steps to reduce bear activity--including the use of secure dumpsters, food composting stations, and the placement of electric fencing around livestock and beehives.

Again and again, residents emphasized that the underlying issue is human behavior. One attendee summarized it succinctly: “There are 3.6 million people in Connecticut and far fewer bears. Human behavior is the problem.”

Lynn Levine, a Litchfield resident who enjoys seeing bears, said common sense steps are the answer. She said that when she first moved to the area, she mistakenly left her garage down open with a 15-pound bag of shelled peanuts inside. "A bear dragged the bag around the side of the garage, sat down and had a teddy bear picnic." She said she learned not to leave the garage door open, especially with food inside.

Not all the stories were lighthearted. An 82-year-old Sharon woman recounted repeated break-ins that left her shaken and facing thousands of dollars in repairs, including a bear walking into her kitchen while she was washing dishes. A veterinarian described livestock attacks, including an alpaca that was mauled and dragged. A farmer said bears caused about $160,000 in crop losses in one year and that cornfields across the region face similar damage.

Several speakers added that DEEP’s limited staffing means local police often end up responding when bears are struck by cars or behaving aggressively.

People are frightened

Cornwall First Selectman Gordon Ridgway, who attended the session, said afterward that he was troubled by how outdated the state’s population data is.

“My biggest personal take-away was surprise — that DEEP doesn’t have a handle on how many bears are here,” he said. “They said they haven’t surveyed them since 2012. How do you make a plan or policy without doing a survey?”

Ridgway said Cornwall has received about 40 bear-related reports this year, including home and vehicle entries and injuries to pets. “People are frightened by intrusions onto their property,” he said. “These are not happy stories.”

He noted that in 2012 -- when the state said it last did its population count -- “a bear was a novelty,” but sightings today are very common. “Today, most people see a bear every week. It’s no longer a novelty — it’s a real issue.”

Ridgway said he supports developing a statewide management plan and wants Connecticut to examine approaches used in other states, including reducing their numbers.

While most attendees at the Dec. 3 session indicated they opposed a hunt, Ridgway said that is not a true reflection of how his constituents in Cornwall view the issue. “If we had a vote, it would be close as to whether there should be a hunting season.”

Only one resident called for a hunt

Only one attendee — a longtime hunter from West Cornwall — advocated for a controlled bear hunt. He argued that the population is “exploding” and that education and bear-proof containers are “a band-aid.” In keeping with DEEP’s rules, other residents did not respond, and the session took place without conflict.

Much of the remaining discussion centered on unsecured trash, short-term rentals, and outdated dumpsters at state parks that residents say train bears to expect human food. Some questioned why the listening session was not better publicized, and Ridgway echoed that concern, saying it should have also been held at the high school to allow more residents to attend.

DEEP collected comment cards at the end of the session. Staff said all feedback will be reviewed as the agency drafts its statewide bear management report.

Keep ReadingShow less

Rick Osborne, manager of the Kent Transfer Station, deposits the first bag of food scraps into a new organics “smart bin.” HRRA Executive Director Jennifer Heaton-Jones stands at right, with Transfer Station staff member Rob Hayes at left.

By Ruth Epstein

KENT — Residents now have access to around-the-clock food-scrap composting thanks to two newly installed organics “smart bins,” unveiled during a ribbon-cutting ceremony Monday morning, Dec. 1.

Rick Osborne, manager of the Kent Transfer Station, placed the first bag of food scraps into the smart bin located at 3 Railroad St. A second bin has been installed outside the Transfer Station gate, allowing 24/7 public access even when the facility is closed.

The initiative is part of a regional effort to expand composting opportunities and reduce the amount of waste sent to state trash facilities. Housatonic Resources Recovery Authority Executive Director Jennifer Heaton-Jones, who attended the ceremony, said the bins demonstrate what small towns can achieve in addressing Connecticut’s broader waste challenges.

“This is proof that even our smallest towns can make a big difference in tackling the waste crisis in our state,” Heaton-Jones said.

Also present at the event was Transfer Station staff member Rob Hayes.

Keep ReadingShow less

Cornwall First Selectman Gordon Ridgway

File photo

CORNWALL — Housing and healthcare topped the list of 15 goals the Board of Selectmen set for the next two years, reflecting the board’s view that both areas warrant continued attention.

First Selectman Gordon Ridgway and Selectmen Rocco Botto and John Brown outlined their priorities during the board’s regular meeting on Tuesday, Dec. 2. On housing, the board discussed supporting organizations working to create affordable options in town, and Botto said the town should also pursue additional land acquisitions for future housing.

On healthcare, Ridgway underscored the importance of mental health services, social services and the town’s Food & Fuel Fund. The selectmen also noted shifts in the regional healthcare landscape, including the opening of the Community Health & Wellness Center in North Canaan and Northwell Health’s new ownership of Sharon Hospital.

Other goals included continuing to work on the West Cornwall wastewater plant, improving the Transfer Station, renovating town buildings, enhancing cell service, working on the Plan of Conservation and Development, supporting volunteer organizations in town, attracting new residents and businesses, creating more recreational resources, public transportation, celebrating America’s 250th birthday and revitalizing the town’s business centers.

“There’s increasing needs for all these things,” said Ridgway.

Winter parking rules

The Dec. 2 meeting was held on Zoom due to snowy conditions in Cornwall. The selectmen said they plan to implement winter parking rules at their next meeting on Dec. 16.

Ridgway also reminded residents to keep vehicles at least 10 feet from the edge of the road so plows can safely clear streets during storms.

Keep ReadingShow less

Classifieds - December 4, 2025

Dec 03, 2025

Help Wanted

CARE GIVER NEEDED: Part Time. Sharon. 407-620-7777.

SNOW PLOWER NEEDED: Sharon Mountain. 407-620-7777.

Weatogue Stables has an opening: for a part time or full time team member. Experienced and reliable please! Must be available weekends. Housing a possibility for the right candidate. Contact Bobbi at 860-307-8531.

Services Offered

Deluxe Professional Housecleaning: Experience the peace of a flawlessly maintained home. For premium, detail-oriented cleaning, call Dilma Kaufman at 860-491-4622. Excellent references. Discreet, meticulous, trustworthy, and reliable. 20 years of experience cleaning high-end homes.

Hector Pacay Service: House Remodeling, Landscaping, Lawn mowing, Garden mulch, Painting, Gutters, Pruning, Stump Grinding, Chipping, Tree work, Brush removal, Fence, Patio, Carpenter/decks, Masonry. Spring and Fall Cleanup. Commercial & Residential. Fully insured. 845-636-3212.

The Villas Cleaning Team: Owner-Operated. Reliable, detailed cleaning by a trusted husband-and-wife team. Homes & Offices. Airbnb. Small Post-Construction. Commercial. Windows. Laundry. Consistent cleaners every time. Competitive rates. Flexible scheduling. Call/Text: 903-918-2390. Dave Villa for a free estimate.

Auctions, Estate Sales

Estate/Tag Sale: 168 Johnson Road, Falls Village CT. Friday Saturday Sunday, December 5th-7th. Total house contents, furniture, antique and vintage collectables, costume jewelry, shed stuff, basement stuff, stairs chairlift, some art. Fri, Sat 9-4 and Sunday 9-noon. A Tommy sale, come and get it!!

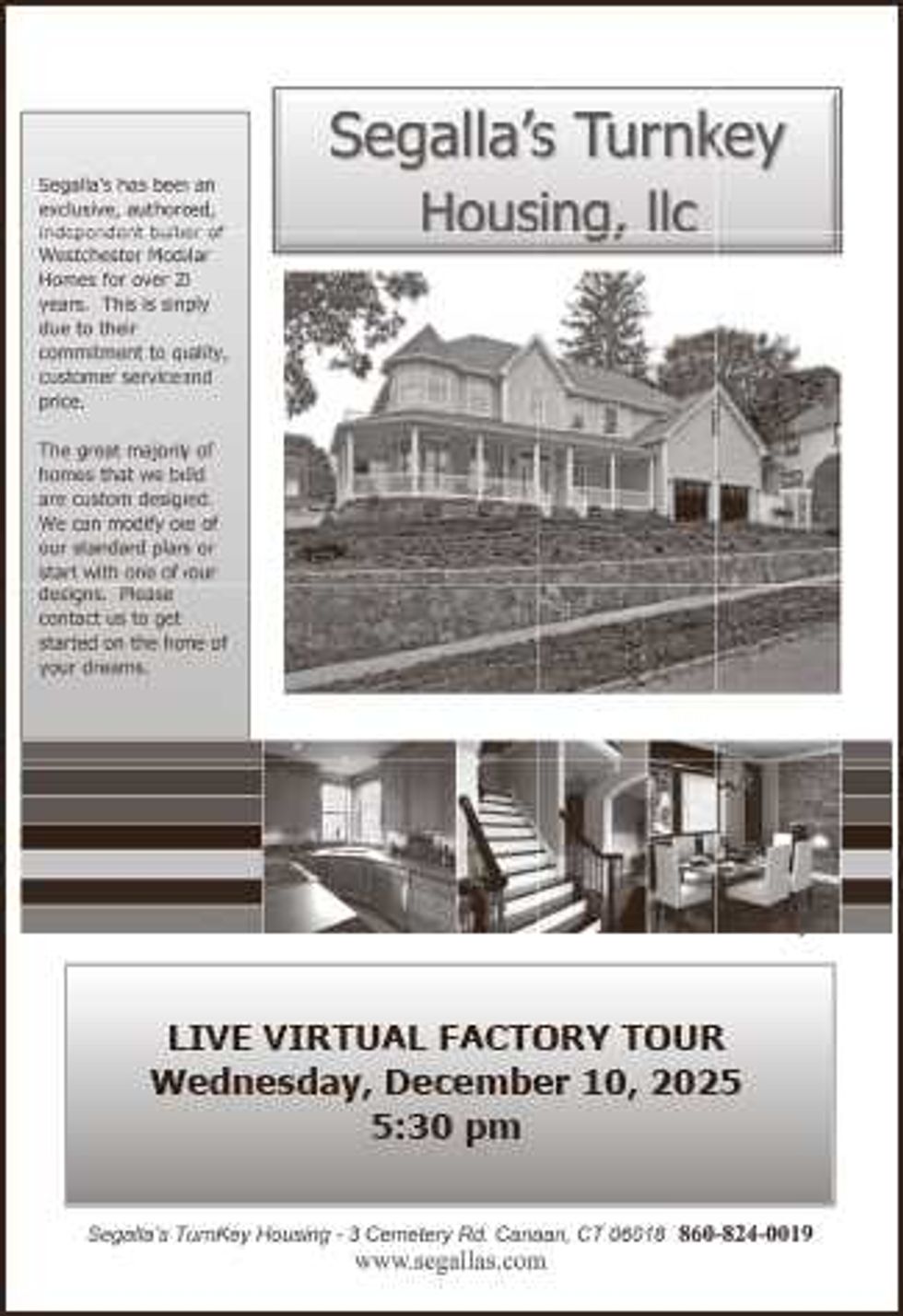

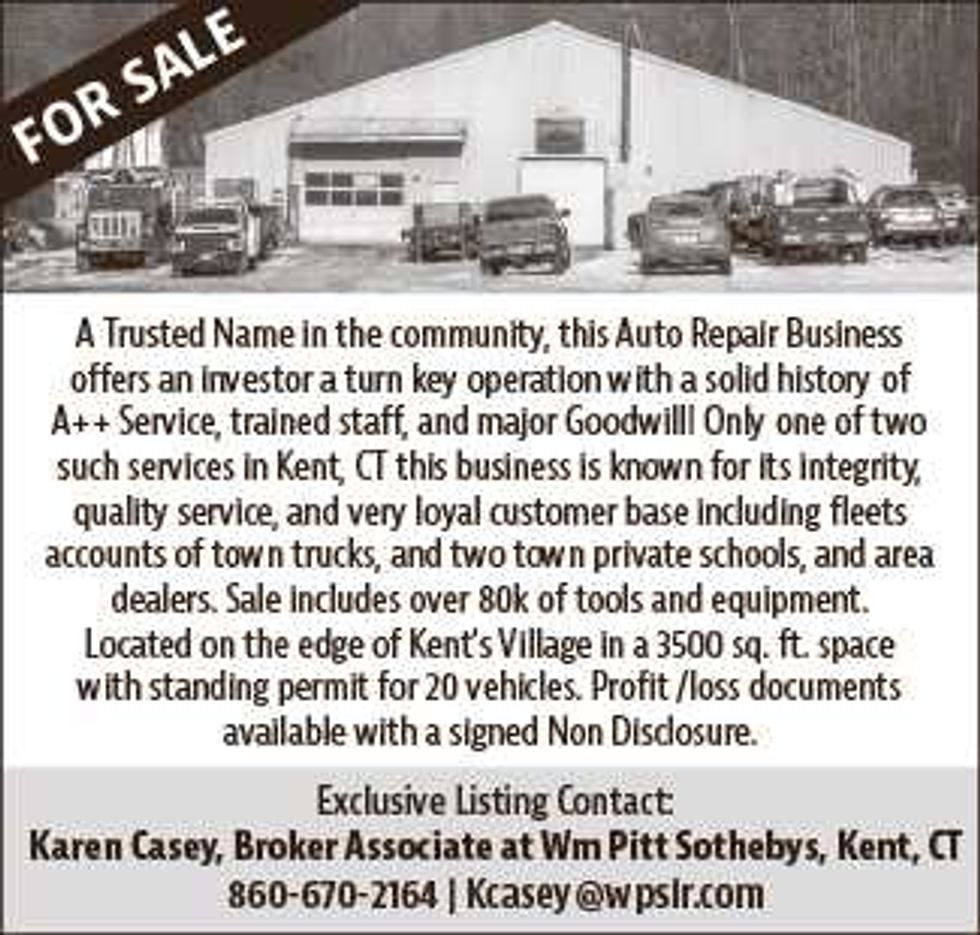

Real Estate

PUBLISHER’S NOTICE: Equal Housing Opportunity. All real estate advertised in this newspaper is subject to the Federal Fair Housing Act of 1966 revised March 12, 1989 which makes it illegal to advertise any preference, limitation, or discrimination based on race, color religion, sex, handicap or familial status or national origin or intention to make any such preference, limitation or discrimination. All residential property advertised in the State of Connecticut General Statutes 46a-64c which prohibit the making, printing or publishing or causing to be made, printed or published any notice, statement or advertisement with respect to the sale or rental of a dwelling that indicates any preference, limitation or discrimination based on race, creed, color, national origin, ancestry, sex, marital status, age, lawful source of income, familial status, physical or mental disability or an intention to make any such preference, limitation or discrimination.

Tag Sales

Sharon, CT

TAG SALE: SATURDAY, DECEMBER 6, 10:00 AM - 2:00 PM, 135 Sharon Mountain Road, Sharon, CT 06069. Clearing things out before the holidays! Stop by for a great mix of items, including: Kitchenware, Small pieces of art, A few pieces of furniture, Clothing, Books, And more assorted household items. Easy to find, everything priced to sell. Hope to see you there!

Keep ReadingShow less

loading